About the product

LED curing technology offers many benefits over traditional Mercury UV curing, such as lower operating costs and No stand by time and No ozone exhaust risks, the only problem for LED curing is wavelength. Compared with mercury UV curing, LED curing system will provide much more energy at single wavelength, such as 365nm,395nm, but Mercury UV curing system provide a “curing area” from UVB to UVA, which is more suitable for current ink system. So it become more important to our clients test their LED ink before they decide to invest LED curing system for their printing or coating machine.

Compared with other suppliers in the market, SpeedyTM use sliding block carry ink sample or radiation meter by Linear Motion system with servo driver +Integrated PLC control to reach precision measurement at speed from 4-300m/min. Our clients set testing speed and UV Energy on Touch screen, Sliding block with ink sample run automatic at the setup speed when it pass the curing area,in the meanwhile lamp will be automatic reach the setup energy. After curing, sample will be automatic return back to the start position. SpeedyTM provide reel-time picture for your curing result same as your printing machines.

Specification

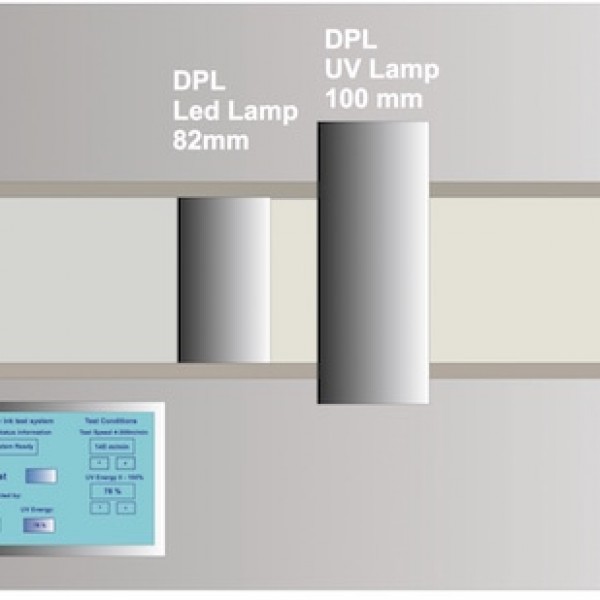

LED Curing Area: 82x60mm or up to client’s request

Peak Wavelength: combination 365-385-395-410nm

Peak Energy Output: up to 26w/cm2

Traditional UV curing (optional):100mm

Speed control: automatic, from 4-300m/min

Control System: Integrated PLC

Power Control Range: 0-100% with instant on-off

Cooling System: closed loop water chilling with automatic flow control

Certifications: CE,UL…

Optional: LED or UV radiation test system - EIT LED-R

Compared with other suppliers in the market, SpeedyTM use sliding block carry ink sample or radiation meter by Linear Motion system with servo driver +Integrated PLC control to reach precision measurement at speed from 4-300m/min. Our clients set testing speed and UV Energy on Touch screen, Sliding block with ink sample run automatic at the setup speed when it pass the curing area,in the meanwhile lamp will be automatic reach the setup energy. After curing, sample will be automatic return back to the start position. SpeedyTM provide reel-time picture for your curing result same as your printing machines.

Specification

LED Curing Area: 82x60mm or up to client’s request

Peak Wavelength: combination 365-385-395-410nm

Peak Energy Output: up to 26w/cm2

Traditional UV curing (optional):100mm

Speed control: automatic, from 4-300m/min

Control System: Integrated PLC

Power Control Range: 0-100% with instant on-off

Cooling System: closed loop water chilling with automatic flow control

Certifications: CE,UL…

Optional: LED or UV radiation test system - EIT LED-R

Contact with supplier

Company